SIM Card system: including card body matting, milling slot package, back glue, half card, and four card matting.

SIM Card personalized distribution: including chip pre-personalized data, chip personalized data reading and writing, and laser marking.

Production management system: including unified production process management, real-time monitoring of production process, equipment status management, and spare parts management.

The value Piotec provides to any SIM manufacturing company extends far beyond individual machines for matting or personalization. The true advantage lies in how our Production Management System unifies these distinct processes. This synergy provides real-time data to optimize every single step, from material use to chip programming, which is key to systematically reducing the SIM card manufacturing cost. By transforming production data into actionable cost-saving strategies, Piotec ensures that every card produced contributes to a more profitable and efficient operation. It is this unique ability to deliver system-wide intelligence and tangible cost savings that makes Piotec the preferred technology partner for many of the industry's top SIM card manufacturers. If you are looking for a partner that prioritizes your bottom line along with technical quality, Piotec is the SIM card supplier that can actually help your business grow.

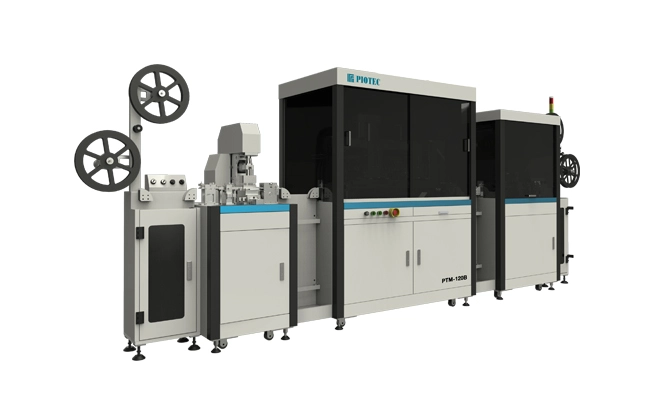

Integrate a number of advanced technologies in the industry (reading and writing technology, laser marking technology, milling groove packaging technology) to achieve efficient, stable and economic goals.

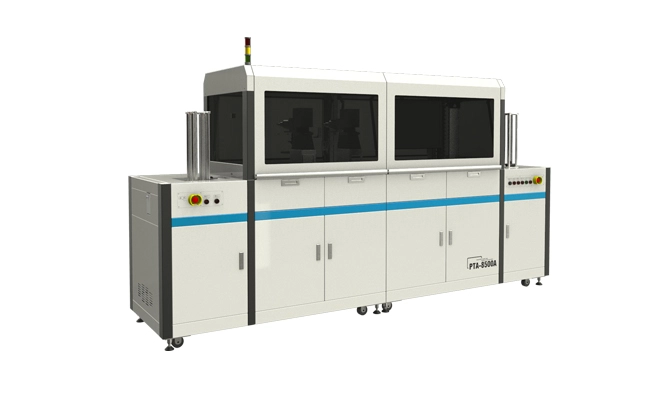

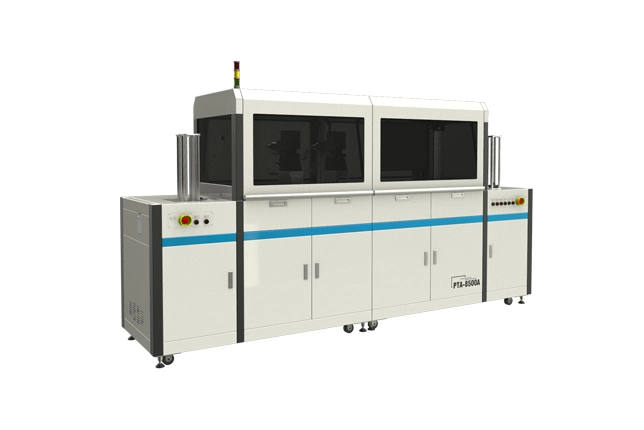

The main equipment (PTA8500A, PTM120T) has been on the market for nearly 10 years and has undergone extensive industry certification to enable the production of one card single core to one card multi-core (up to eight cores).

There are rich types of equipment and complete models, and according to customer needs and actual conditions (existing equipment, site environment), the production line can be flexibly combined.

Self-developed customized production management system, powerful, to promote intelligent factory production.

High-Quality Production: We use advanced technology and high-quality materials to ensure the durability and reliability of our SIM cards manufacturing.

Security: Our SIM cards are designed with robust security features to protect against data breaches and unauthorized access.

Customization: We offer customization options to meet the specific needs and requirements of our clients.

End-to-End Solution: Our solution covers the entire process from design and production to issuance, ensuring a seamless experience for our clients.

Expert Support: Our dedicated team of experts provides continuous support and guidance throughout the process.

Efficiency: Our manufacturing and issuing process is streamlined and efficient, ensuring timely delivery of SIM cards.

Scalability: Our solution is scalable, capable of handling orders of any size, from small batches to large-scale production.

The application of SIM Card Manufacturing and Issuing is vast and crucial in today’s digital age. It plays a significant role in the telecommunications industry, enabling mobile devices to connect to cellular networks for voice calls, SMS, and internet access.

In addition, SIM cards are also used in various IoT devices for secure data transmission. They are used in smart home devices, industrial automation, vehicle tracking systems, and more.

Furthermore, with the advent of eSIM technology, the application of SIM card manufacturing and issuing has expanded to wearable devices, tablets, and other smart devices.

Piotec's SIM Card Manufacturing and Issuing Solution ensures the production of high-quality, secure, and efficient SIM cards for these diverse applications. Piotec, your go-to SIM card supplier, ensures safe, compatible, and cost-effective SIM cards for global connectivity solutions. When you partner with us, you are getting the rigorous quality standards and reliability you’d expect from a top sim card manufacturer.