The equipment contains a number of independent research and development of core advantages of technology (whole machine research and development capabilities, supporting integration capabilities, independent research and development of industrial high-speed reader, visual recognition system, laser marking machine), to achieve higher production capacity, higher compatibility and stability of the equipment.

The wide application of independent research and development parts, effectively reduce the customer's early procurement costs; The number of wearing parts is small and the life is longer, which effectively reduces the customer's later maintenance costs.

From equipment hardware, to supporting application software, and even to supporting consumables, we can provide users with perfect solutions, and the three can achieve deep coordination and further reduce user procurement costs.

including self-developed industrial high-speed reader, visual recognition system, laser marking machine, etc., to achieve higher production capacity, higher compatibility and stability of the equipment.

the wide application of independent research and development parts, effectively reduce customer procurement costs; The number of wearing parts is small and the life is longer, which effectively reduces the customer's later maintenance costs.

From equipment hardware, to supporting application software, and even to supporting consumables, can provide users with perfect solutions, and can achieve deep coordination among the three, further reducing user procurement costs.

Take the initiative to maintain in-depth interaction with customers, the first time to understand customer needs, the first time to solve customer problems, to meet and exceed customer expectations.

Design: The first step involves designing the chip according to the specific requirements of the application. This includes determining the memory size, processing power, and security features.

Wafer Fabrication: The design is then used to create a silicon wafer, which is a thin slice of semiconductor material. This is done using a process called photolithography, where the design is etched onto the wafer.

Dicing: Once the wafer has been fabricated, it is cut into individual chips. This process is known as dicing.

Packaging: The individual chips are then packaged to protect them from physical damage and environmental factors. This involves placing the chip in a protective casing and connecting it to the contact points that will allow it to interface with the smart card.

Testing: The packaged chips are then tested to ensure they function correctly. This involves checking their electrical characteristics and verifying that they can correctly execute their intended functions.

Embedding: The personalized chips are then embedded into the smart cards. This involves attaching the chip to the card and connecting it to the card’s contact points.

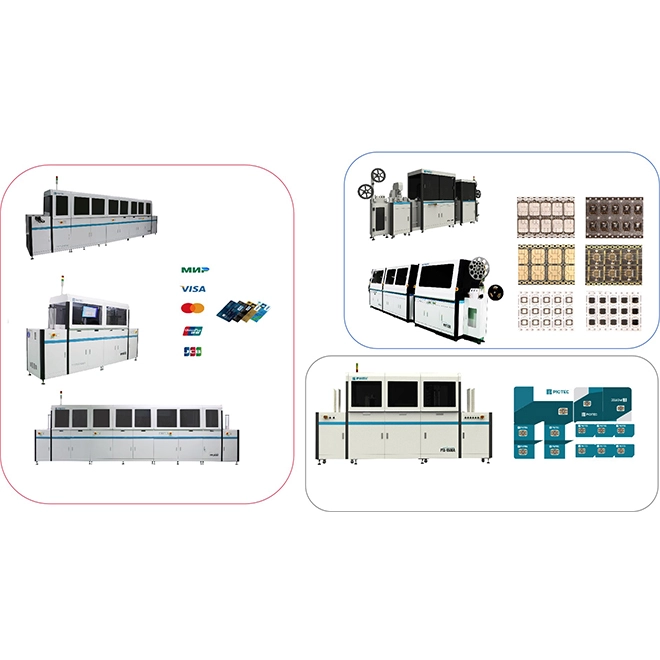

In the smart card personalized industry, PTA-8500 series equipment can write chip data to all kinds of telecommunications cards, card surface laser marking and information verification and other large-scale personalized production. Flexible bank card personalized production line FPL6081 series equipment can be selected according to the needs of data writing, lithography, convex and concave characters, hot printing, visual verification and detection functions. PTM-120 series equipment can perform various types of chip module strip, chip electrical performance test, chip initialization and other operations.

In the intelligent card system manufacturing industry, we can provide equipment for the whole process (including stacking, laminating, matting, hot stamping, milling groove packaging, and attaching gold labels, etc.).

In the M2M semiconductor chip personalization industry, SCM3000 series devices can perform chip electrical performance testing, chip personalization data writing and surface laser personalization printing for M2M chips in various packaging forms, automotive electronics SE(Security Element- security chip), eSIM and other intelligent devices.

In the card manufacturing and personalized industry, we can provide various materials (including (Metal, PC, PETG, PVC, PET, Teslin, Paper, etc.) card system manufacturing equipment and personalized equipment including data writing, laser printing and other functions.

In the financial services terminal industry, it can provide all the terminal equipment used by banks and other financial institutions. Including instant card issuing equipment, deposit and withdrawal equipment, cash machines, cash boxes, safes and other equipment.

In the semiconductor manufacturing industry, DIE-BONDER, WIRE BONDER, automatic cutting and sorting, precision slicing, thin film stripping machine, AOI and other equipment are currently available.

At the same time, it can provide industrial intermediate products (reader, laser, vision system, INLAY tester), software (production management system, bank card personalized issuance system, financial terminal service system platform, etc.) dedicated to each equipment. Supporting consumables (epoxy film plastic for semiconductor packaging, UV adhesive, DOD ink, ribbon, metal cutter materials, special bank card body materials, etc.)