The desktop Inlay tester and Encoder is a multi-purpose testing device designed for Inlay and RFID card/tag vendors to support mainstream 3X8 Inlay read-write testing, open short circuit test, leakage current test, UID test, ATS test, multi-protocol label Mixed Test, encryption test and so on.

The supported protocols include ISO14443A, ISO14443B, ISO15693, etc. .

The Inlay desktop tester is equipped with large-size LCD touch screen, easy to operate, intuitive display of rich information, and can achieve data recording, statistics and data export.

The compact shape and extensive support ensure that the tester can be used in a variety of scenarios, both simple and convenient.

The products can be customized according to customer needs and specific features.

| Main configuration | Details | Specifications |

Ethernet interface | Access | Road 1 |

| Communication rate | 10M/100M Adaptive | |

| Interface type | RJ45 | |

| USB interface | Access | Road 1 |

| Communication standards | USB3.0 | |

| Interface type | Tybe-A | |

| Button box interface | Access | Road 1 |

| Signal type | Di input | |

| Interface type | Aviation plug | |

| Display screen | Size | 23.8 inches |

| Type | LCD touch screen, capacitive 10-touch | |

| Resolution | 1920×1080 | |

| Power supply | Rated voltage | 220V |

| Maximum power | 100W | |

Mechanical parameters (This is a reference value, based on user requirements) | External dimensions | 780mm(L)×460mm(W)×210mm(H) |

| Weight | 45kg | |

| Environmental parameters | Operating temperature | 0℃~50℃ |

| Storage temperature | -20℃~60℃ |

Serial number | Name | Description |

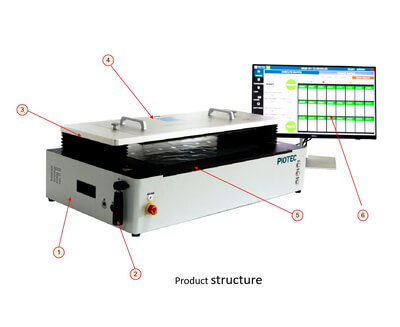

1 | Box body | The main body of the device comprises contact readers, contactless readers, RF boards, core boards and other electrical components. |

2 | Adjust the handle | Push the handle to a different scale, you can adjust the distance between non-connected readers to detect different sizes of materials. |

3 | Lifting mechanism | Drive the contact needle plate up and down. |

4 | Contact needle plate | 3 different sizes of needle plate for different sizes of materials. |

5 | Panel | The position mark is painted on the panel, and the materials of different sizes are aligned with the corresponding position mark when discharging, so as to realize the position of the materials and the needle plate. |

6 | Touch screen | Test instrument interface display, operation and start-up test. |

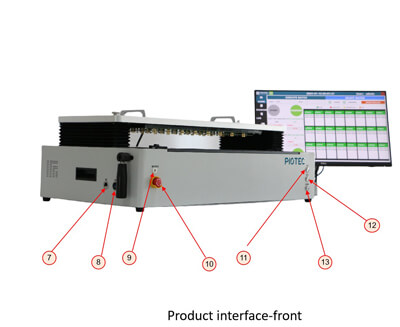

7 | Network interface | The device interfaces with an external network connection. |

8 | USB Interface | The device is connected to an external USB Interface. |

9 | Emergency stop button | An emergency stop switch. |

10 | Static ring socket | Connect the operator to the electrostatic bracelet. |

11 | Start button | After the Start button is pressed, the device starts to test the action. |

12 | Retest button | After pressing the button, the device reboots to begin the test action. |

13 | Confirm button | After pressing the button, confirm the test result. |

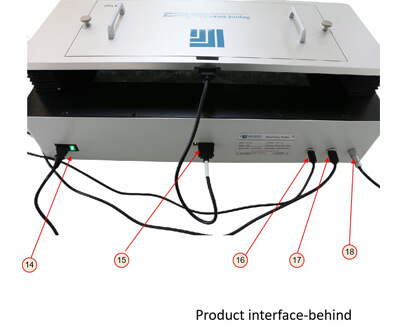

14 | Switch socket | Responsible for the main power switch of the equipment. |

15 | Contact pin plate socket | Contact needle plate and contact reader quick-change socket. |

16 | USB Interface | The interface between the display and the device. |

17 | HDMI Interface | The interface between the display and the device. |

18 | Button box interface | Control the connection interface between the button box and the device. |

19 | Up button | Control the lifting mechanism rising during maintenance and debugging. |

20 | Drop button | Control the lowering of lifting mechanism during maintenance and debugging. |

Fast test speed, easy operation, large size LCD touch screen, interface test results more intuitive.

Can realize the contact/non-contact double interface detection function simultaneously;

Support including ISO14443A, ISO14443B, ISO15693 and other protocols;

Support UID, ATS, multi-protocol tag mixing and encryption and other tests.

Extensible to support custom development of a variety of layout, protocol INLAY material.

Can use touch screen operation, chassis button operation and external button box operation.

Contact Piotec for Smart Card Solution